VIBRATING FEEDER BUNKERS

Leading the sector with 19 years of knowledge and experience.

TBX-25

Vibrating Feeder TBX-25 is mainly used as rock feeder in quarries. TBX-25 , which has a length of 700 mm and a width of 3000 mm, is the most preferred model in this product group due to its minimal footprint.

| FREEDER WIDTH | 800 mm | HOPPER VOLUME | 25 m3 |

| FREEDER LENGTH | 3150 mm | CAPACITY | 100-200 TPH |

TBX-35

The Vibrating Feeder TBX-35 is ideal for crushing plants with a stone feeding capacity of 270 tons per hour. These work machines, occupy 1000 × 3750 mm in size. The vibrating feeders contribute to the production with serial material feeding in the new facilities established by the companies working with the understanding of quality service to get high performance.

| FREEDER WIDTH | 950 mm | HOPPER VOLUME | 35 m3 |

| FREEDER LENGTH | 4000 mm | CAPACITY | 200-300 TPH |

TBX-45

Vibrating Feeder TBX-45 is ideal for getting faster and higher capacity service in facilities where the hardest stones are crushed. Companies aiming to provide high performance can easily use this product, which has a stone feeding capacity of 400 tons per hour.

| FREEDER WIDTH | 1100 mm | HOPPER VOLUME | 45 m3 |

| FREEDER LENGTH | 4800 mm | CAPACITY | 300-400 TPH |

TBX-55

Vibrating Feeder TBX-55 is an ideal work machine for high performance crushing and screening plants. Providing feeding thanks to 2 vibro motors working in different directions, TBX-55 is the most ideal vibrating feeder for large enterprises with a capacity of 400-800 tons per hour.

| FREEDER WIDTH | 1300 mm | HOPPER VOLUME | 55 m3 |

| FREEDER LENGTH | 5000 mm | CAPACITY | 400-500 TPH |

Tracked Feeder

Apron Feeders are a type of mechanical feeder used to transfer material to a crusher or other downstream equipment at an even rate.

Apron Conveyor Feeder

Conveyor Belt feeders are short belt conveyors specially designed to regulate material flow, pulling material from a single area and allowing subsequent equipment to receive the appropriate volume.

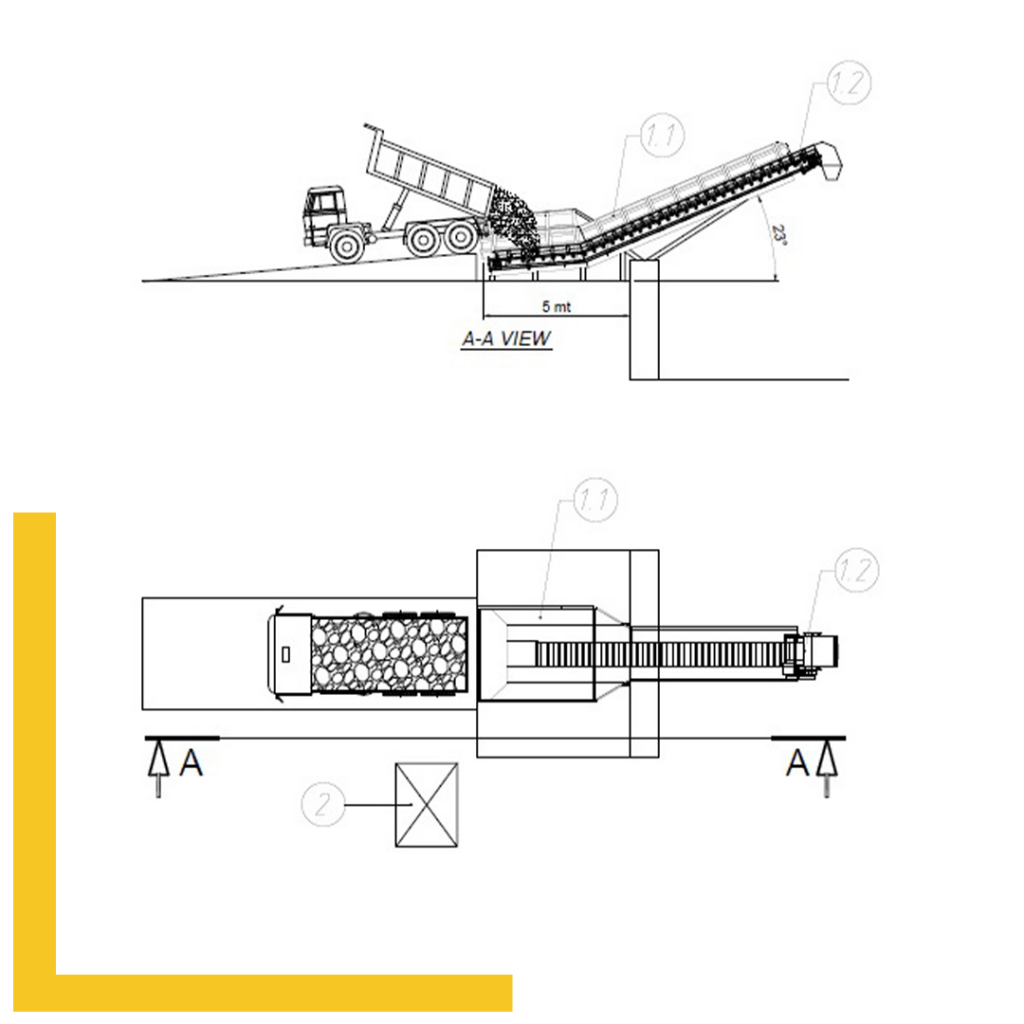

VIBRATING FEEDERS DETAIL

Vibrating Feeder Bunker makes pre-feed of quarry material/pieces of large rock to primary jaw crusher and primary impact crusher. Vibrating Feeder Bunker is the first on the crushing process of plant by material feeding to crusher after making vibration with two vibro motor. Inner sides are covered with abrasion resistant steel plates st-52 and bolted adjustable linings and also can be replaced without damaging the main body after abrasion of the liner on the upper side.

Vibrating Feeder Bunker have grid screen on it. This screen is thrown to the stock as bypass with increase two steps without going into the crusher at where the soil bypass material is a lot. So that aggregate become clean and the desired quality.